Welcome to our Insight blog where you will find stories and announcements that pertain to the industries Pyrotek serves, from aluminium to zinc galvanizing to glass to acoustics to battery materials and more.

ConMet Mexico Turns to Pyrotek Graphite Shafts and Rotors

by David Cole | 17 February 2025

ConMet’s facility in Monterrey, Mexico, which makes aluminum castings for the heavy trucks industry, has found that switching to Pyrotek’s graphite shafts and rotors used in degassing processes has reduced maintenance downtime, allowed for more efficient stocking of supplies, and ensured customer orders are fulfilled on-time.

CONTAINER GLASS: How Low-Porosity Refractory Stirrers Boosted Plant Efficiency

by David Cole and Paul Chevolleau | 28 October 2024

The right refractory material for stirrers in a colorant forehearth can eliminate streaky glass and increase plant efficiency and safety.

New Technology from Pyrotek to Display at EUROGUSS 2024 – MCS-V Furnace

by David Cole | 10 January 2024

A technology that many aluminium high-pressure and low-pressure die casters have been calling for will be featured at EUROGUSS 2024 – a new Pyrotek innovation that advances performance and sustainability. The Pyrotek Metal Casting System - Vacuum.

Pyrotek Installs Another Integrated Melting System (IMS) at Customer Site

by David Cole | 14 August 2023

The IMS consists of equipment specifically engineered to process machining chips, converting it efficiently back to usable metal.

Pyrotek Rigid Glasweve® Filters Help Foundries Accelerate Toward Sustainability Goals

by Andrew Carlson and David Cole | 18 July 2023

Pyrotek developed the RGW filter technology to give its foundry partners in the aluminum industry critical efficiencies to be more competitive for years to come. Technology for greater sustainability and process efficiency is where Pyrotek continues to dedicate its research and development resources around the world.

Electromagnetic Priming of Aluminium Filtration Systems: Pyrotek EM-DF

by David Cole | 17 February 2023

Learn about the Pyrotek Electromagnetic Deep Filtration (EM-DF) System

Come and visit us at the TMS 2023 Annual Meeting & Exhibition March 19–23, 2023 | San Diego Convention Center & Hilton San Diego Bayfront.

Major Foundry in Spain Installs Pyrotek Degassing Units to Optimize Metal Treatment

by David Cole and Saul Gracia Villacampa | 31 January 2023

MAPSA Has Chosen Pyrotek for Advanced Degassing Technology Expansion.

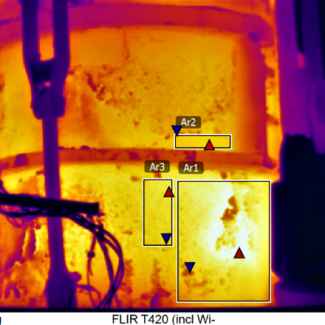

CASE STUDY: Steel Plant Reduces Energy Loss by Choosing ISOMAG Structural Insulation

by David Cole | 1 November 2022

Pyrotek delivered an insulating solution that enabled a customer in Eastern Europe to reduce energy consumption related to their steel ladle by EUR€250,000 per year and delivered a return on their investment in less than three months.

USA Plant Recruitment Videos Earn Telly Award

by David Cole | 12 July 2022

The USA manufacturing plant videos, produced last year by Pyrotek Global Marketing to support critical ongoing recruitment efforts and promote the facilities more broadly, are the recipient of a 2022 Telly Award.

Pyrotek Receives Contractor Award from Constellium Muscle Shoals

by David Cole | 7 June 2022

Constellium Muscle Shoals' aluminium manufacturing operation in Muscle Shoals, Alabama, USA, presented Pyrotek with a "Contractor of the Year Award," following molten metal furnace refractory relining and maintenance work. Since 2015, Pyrotek's refractory services team has been providing refractory linings for furnaces, crucibles, and troughs for Constellium Muscle Shoals.

Ceramite Dual-Cast Crucibles Offer Maximum Life

by David Cole | 1 June 2022

At 2.5 tonnes capacity for molten metal, a Pyrotek Ceramite® Dual-Cast Crucible transfer ladle is the largest in use today at any foundry in Western Europe. It’s currently performing successfully for premium automotive foundry in Germany.

Blansko Earns Renewable Energy Certificate

by David Cole | 17 May 2022

As the European aluminium industry keeps pushing suppliers to be more "green," Pyrotek Blansko is already in a great position to meet targets as leaders there have made sure operations run sustainably using renewable energy sources.

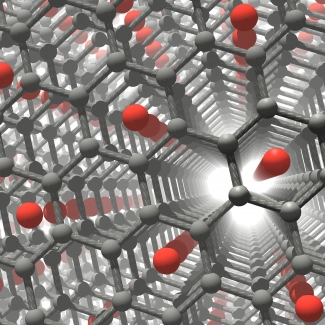

Anovion Launches as a Leader in the North American Battery Materials Supply Chain Bringing Proven Anode Technologies and Over 140 Years of History in Synthetic Graphite Production

Anovion launches as a leader in the North American battery materials supply chain through the combination of key assets contributed by affiliates of Amsted Graphite Materials, a world leader in graphite materials science, and the acquisition of Pyrotek’s battery materials division, a manufacturer of synthetic graphite anode material critical for lithium-ion batteries.

Pyrotek Delivers Experienced Furnace Cleaning Services

by David Cole | 8 February 2022

Pyrotek safely cleans furnaces and associated launders, removing dross, corundum, and oxides by utilizing specialized tools, fluxes, and inert gas when necessary.