Power Generation

Extend power station outage cycle time

Short outage cycles and component replacement costs have long-hindered the power generation industry. Over time—often short periods of time—intense heat deforms and destroys a plant’s stainless steel burner tubes and nozzles and other components.

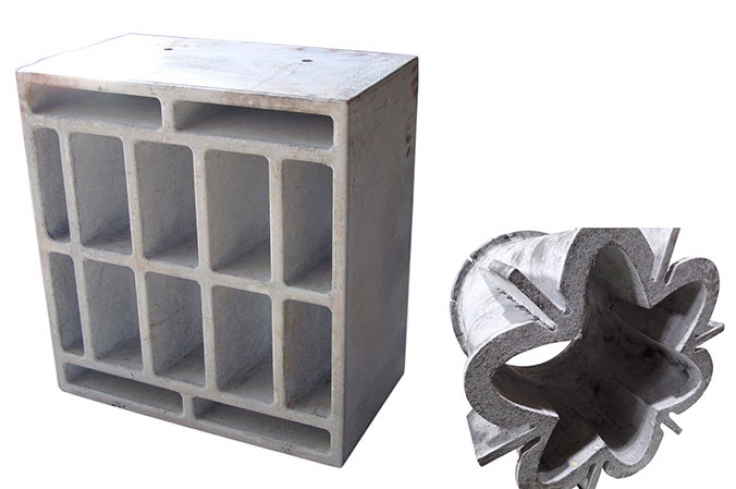

In coal-fired power plants, intense boiler temperatures of up to 1100°C instantly flash water to steam to create the pressure required to spin turbines to power generators. The intense heat warps, erodes and degrades stainless steel burner tips, reducing performance, necessitating costly maintenance and taking the system out of operation for many weeks and costing millions of dollars in time, materials and lost revenue.

Pyrotek has captured the strength and durability of Ceramite® and Ceraforte® refractory to transform coal-fired power plant outage cycle times, in many cases tripling the effective lifespan of critical and costly high-temperature components.

Benefits include:

- Increased durability

- High mechanical strength

- Resistance to high temperature and thermal shock

- Reduced downtime

- Smaller environmental footprint

View our Ceramite for power generation brochure.

Related Products

Ducting

Expansion Joints

High Temperature Covers and Lids

High Temperature Gaskets and Seals

Instrumentation and Control

Refractory

Refractory Shapes

Thermal Covers

Thermal Insulation

More

- Burner Nozzles and Equipment

- Fume Ducts

- High Temperature Gaskets

- Thermal Insulation

- Thermal PPE