Welcome to our Insight blog where you will find stories and announcements that pertain to the industries Pyrotek serves, from aluminium to zinc galvanizing to glass to acoustics to battery materials and more.

Pyrotek Coatings Expert: Right Product and Application Will Protect Your Capital Investments and Improve Your Metal Quality Now

by David Cole | 30 July 2020

Choosing the correct coating and using it wisely will extend the life of a substrate, and, the better the coating, typically the more casts obtained between recoating activities.

Pyrotek Works Closely with Cometal Engineering At New Alu Menziken Casthouse in Romania

by David Cole | 15 July 2020

Convinced of Pyrotek's high-performance solutions, Cometal turns to Pyrotek for the best technology in launder systems, filtration, degassing and refining.

Pyrotek Single-Chamber Underheated Furnace Provides Advanced Technology in Smaller, Compact Size

by David Cole | 7 July 2020

“Our single-chamber furnace is smaller than the dual-chamber design, and by fitting under a casting station they don't take up additional floor space,” says Tomáš Mazálek, Foundry Furnaces Project Manager for Pyrotek’s Blansko Engineering Center.

Customers Enhance Their Process Technology with Pyrotek Advanced Control Panels

by David Cole | 17 June 2020

Pyrotek is recognized globally as a design-and-build leader of advanced control panels for electric heating systems, gas combustion systems, and other automated control systems.

Full Project Management and Engineering Services with Pyrotek

by David Cole | 9 June 2020

As manufacturers have had to reduce the number of in-house technical staff members they employ, they have grown increasingly more reliant on Pyrotek and other vendors for engineering and technical expertise.

Improve Glass Tempering Furnace Efficiency with Pyrotek Roller-End Side-Seals

by David Cole | 5 June 2020

Stop losing heat and allowing profits to slip out the side of your tempering furnace. Regain greater control of temperatures inside your furnace. Pyrotek’s roller-end, side-seal refractory shapes deliver both greater efficiency and control.

RFM® Ladles Save Foundries from Frequent Changes, Downtime, Metal Sticking

by David Cole | 4 June 2020

Pyrotek reinforced fiberglass material (RFM®) ladles are helping foundries around the world cut way down on inclusions flowing into their finished castings, and reducing the frequency of ladle-change stoppages caused by metal sticking and wear.

Ceramite Launders – For Maximized Strength, Service Life, and Performance

by David Cole | 2 June 2020

Aluminium industry plants around the world have found they can improve their operational efficiency and increase profitability by using launders made with Pyrotek’s advanced strength Ceramite material, which is manufactured in a variety of blends for every specific application.

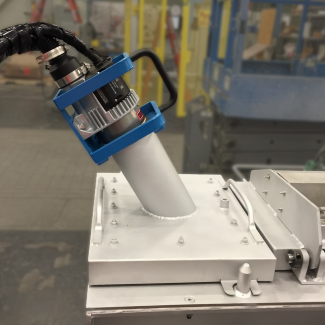

Precise, Safe, and Portable Heating with Pyrotek Zen Preheater Systems

by David Cole | 29 May 2020

Many aluminium foundries and casthouses around the world rely on Pyrotek’s compact and portable Zen heater units to preheat refractory parts and other operational components.

Demand More from Your Degassing Consumables with RFM® Sleeved Degassing Shafts

by David Cole | 26 May 2020

Maximizing the lifetime of graphite degassing consumables is critical to decreasing downtime and improving process efficiencies.

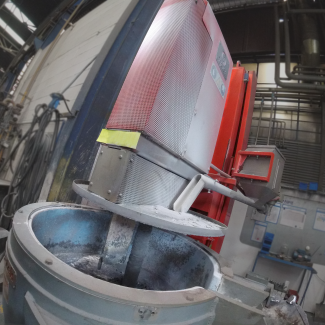

Maximizing Safety and Improving Efficiency with Sow Furnace Technology

by David Cole | 14 May 2020

In a charge of 40,000 pounds of prime aluminium T-bar or ingot/sow, he saw a reduction of melt times from 7 hours to 4 hours. He also saw an increase in production of 35,000-70,000 pounds in the first month of use.

Pyrotek RFM Drain-Out Pump Reduces Pump Times and Maximizes Efficiency

by David Cole | 12 May 2020

Pyrotek reinforced fiberglass material (RFM®) drain-out pumps are helping world-class foundries around the world more effectively empty holding and melting furnaces.

Increasing Ladle Efficiency and Service Life Through Proper Preheating Technology

by David Cole | 4 May 2020

“It’s crucial that our customers get the highest performance from their transfer ladles and have the safest, most efficient process of preheating them,” says Mike Tomassi, Chief Engineer at Pyrotek’s Cortland, New York, USA, facility. “Our transfer ladle preheat systems help operators properly heat their vessels so they can spend more time operating and less time in maintenance.”

CASE STUDY: STAR E3500 Degassing Unit Delivers Stable Metal Density

by David Cole | 12 April 2020

Pyrotek’s STAR E3500 degassing unit with Programmable Logic Controller (PLC) is helping foundries achieve stable metal density regardless of alloy or input conditions, which is critical to a successful casting process.

Pyrotek Completes New Dubai Manufacturing Plant

by David Cole | 6 April 2020

Pyrotek Inc. has completed construction of a new manufacturing facility in Dubai, United Arab Emirates, to serve and supply the rapidly growing aluminium smelting operations of the region.