High-Pressure Die Casting

The trend to make vehicles lighter and more efficient is increasing the demand and potential for high-quality structural aluminium castings. This increased demand is an excellent opportunity for plants willing to invest in the high-pressure die casting process. The high-pressure die casting (HPDC) process can produce high-integrity castings at competitive costs compared to other process technologies. Most casting defects result from poor quality metal due to oxides, hydrogen content, sludge and dross. High-integrity die casting requires significantly improved metal quality compared to standard die cast aluminium applications. Thus, metal quality is essential. These quality demands require that plants better manage every stage of the HPDC process.

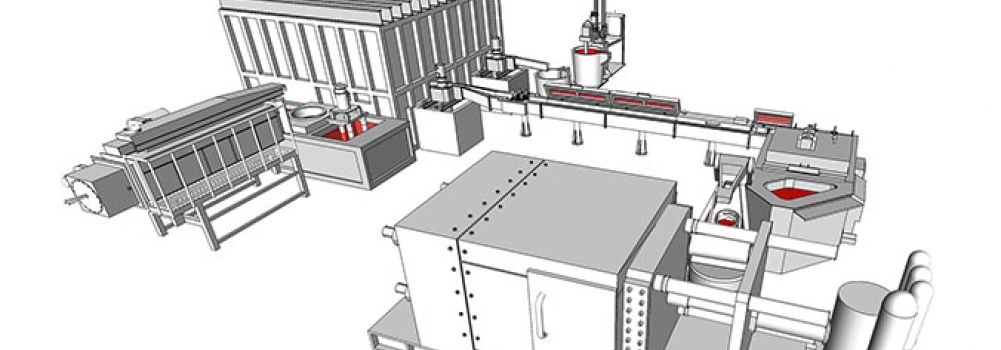

Pyrotek’s foundry team focuses on improving metal quality and die casting performance with integrated systems for melting, metal holding, transfer and metal treatment. Solutions for HPDC include furnaces, pumps, degassing equipment, ladles, filtration and more.

- Improved metal quality

- Reduced scrap

- Increased process efficiency