Transition Plates and Header Plates

Overview

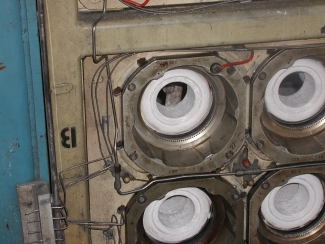

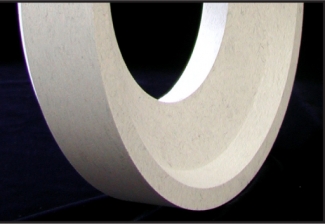

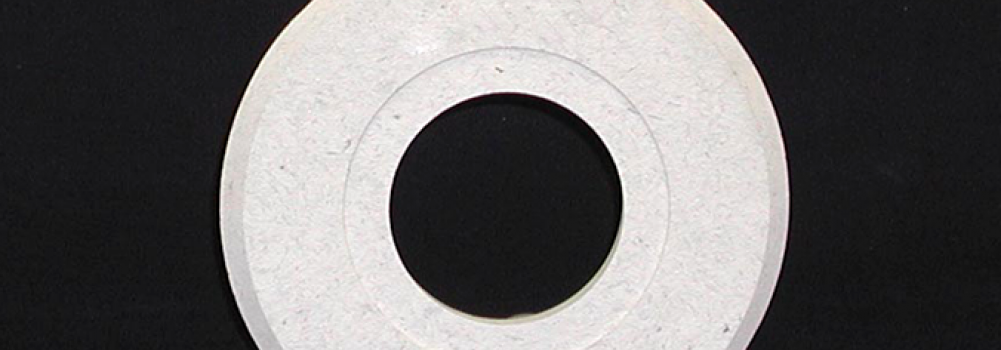

Pyrotek Transition Plates for VDC machines and Pyrotek Header Plates for HDC machines are replaceable ceramic components installed in the billet mould assemblies. They create the leading boundary of the mould before primary solidification at the mould. The axisymmetric transition plates for VDC applications are available in the full range of geometries for all casting machnie technologies. Similarly, Pyrotek’s HDC transition plates can be manufactured in almost any diameter and aperture that is required.

Pyrotek Offerings

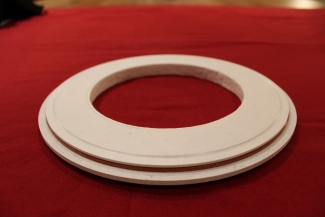

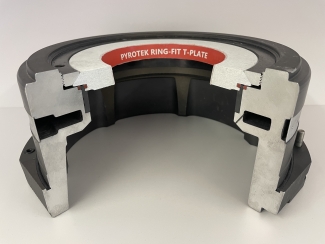

Pyrotek offers two products for billet casters from a variety of materials. Our Original Equipment Replacement (OER) Transition Plates are manufactured to OEM specifications to ensure proper fit and function. They are offered in three different carbon fiber reinforced calcium silicate materials including N-17, CS-1, and N-600. N-17 is the preferred material choice for most applications; however, the alternatives offer benefits to those casting with thick transition plate designs and large diameters. The reduced permanent shrinkage of CS-1 and N-600 in these situations can eliminate the need to retighten the mould assemblies and prevent fractures in diameters larger than 254mm (10”). Pyrotek Ring-Fit Transition Plates are an exciting new product we have developed from years of research. By engineering unique geometries and adding a locator component, concentric installation is achieved every time and stress is reduced to extend service life and reduce both the likelihood of fracture and distortion of the component. The locator and the feature to hold it can also help to reduce both oil penetration and heat loss. Like the OER Transition Plates, Ring-Fit Transition Plates are made from either N-17, CS-1, or N-600 with N-17 the proven choice for most applications.

- Machined to stringent tolerances to ensure fit and function

- No refractory ceramic fibers (non-RCF) to comply with local regulations and improve the health and safety of workers

- Low thermal conductivity to ensure solidification occurs at the mold

- High toughness to manage strain and stress during operation

- Thermal shock resistant to ensure successful cast start, and non-wetting to provide oxide mobility during casting

| 1127 Refractory Board Products EN | Datasheet | English |

| 1827 Pyrotek Ring-Fit Transition Plates EN | Datasheet | English |

| 1818 Pyrotek Transition Plates VDC and HDC EN | Datasheet | English |

| 1651 Vertical Direct Chill Billet Casting Brochure EN | Brochure | English |

| 1875 Pyrotek Fracture Guard Transition Plates EN | Datasheet | English |