Pyrotek Ring-Fit Transition Plates

Overview

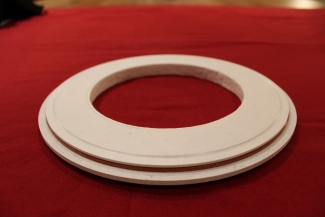

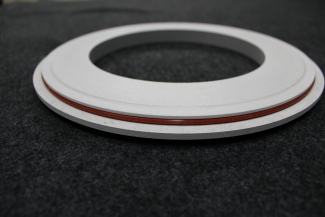

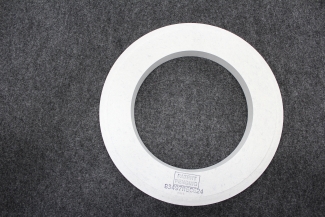

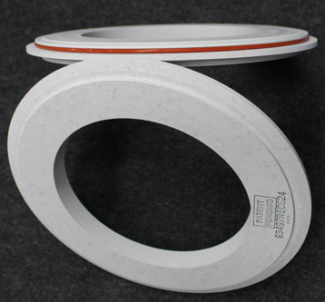

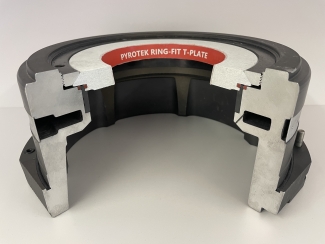

Pyrotek Ring-Fit Transition Plates are replaceable ceramic components installed in direct chill (DC) billet mould assemblies. They create the leading boundary of the mould before primary solidification at the casting ring. Unlike traditional transition plates, concentricity to the mould bore during installation is automatic with Pyrotek Ring-Fit Transition Plates since they have a locator installed on them.

The unique design also assists with steady state operation when thermal stability of the system is achieved. By engineering the optimal allowance for thermal expansion, thermal stress is significantly reduced to extend service life and reduce the risk of premature failure. This allowance also changes heat transfer modes at the casting ring interface to convection from conduction to reduce heat loss and improve control of primary solidification. It also reduces maintenance requirements by minimizing distortion that abrades and strains joints to thimbles and decreasing compression of joints to tabletop refactory.

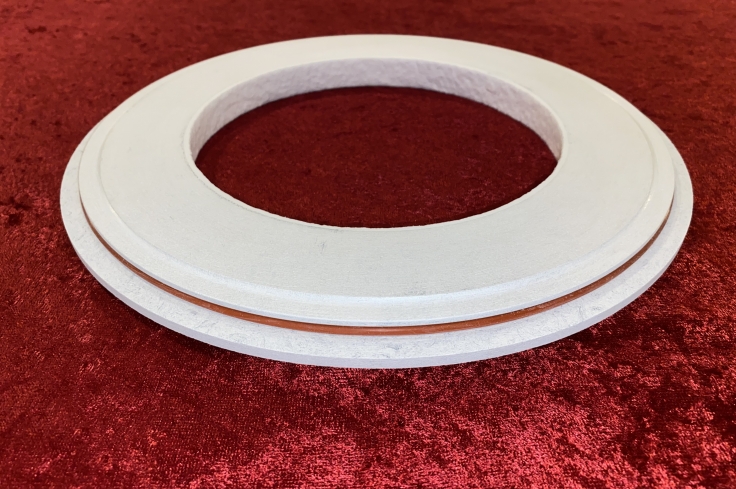

Pyrotek Ring-Fit Transition Plates are made from Pyrotek N-17 carbon fiber reinforced calcium silicate and include a high-temperature silicone locator, a Unifrax Fiberfrax® 970J ceramic paper gasket (where used), and factory-coated ZYP Boron Nitride Lubricoat EAS-25 protective coating. Other configurations are available.

| 1127 Refractory Board Products EN | Datasheet | English |

| 1827 Pyrotek Ring-Fit Transition Plates EN | Datasheet | English |