Gravity Casting

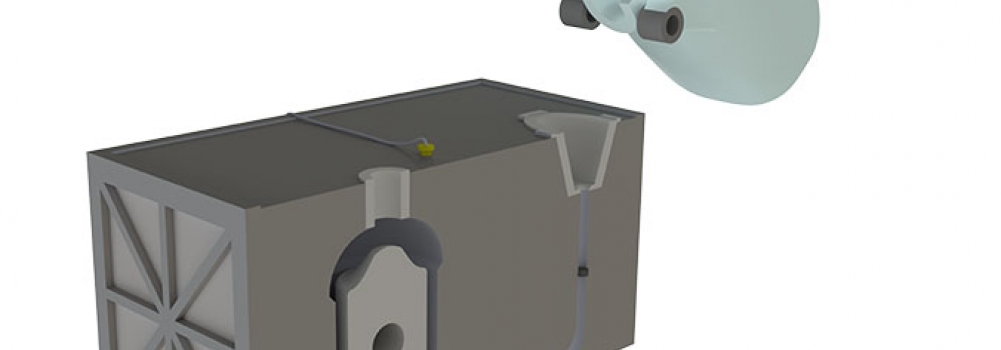

In gravity casting, foundries use gravity to transfer molten aluminium into casting moulds. Liquid metal may be poured or dosed into the moulds, usually through a filling funnel. Gravity forces the poured metal into the mould cavities where it forms into a cast piece. Different gravity casting processes can be distinguished based on the types of materials that make up the mould an operation uses. The three primary mould types include: permanent (metal mould), semi-permanent (metal and sand mould) and sand only moulds. Critical issues include porosity within cast parts, metal pouring temperature, shrinkage cavities, incomplete mould filling, melt cleanliness, metal buildup and mould release.

Within gravity casting operations, Pyrotek products provide a wide range of solutions, including transfer ladles, refractory furnace linings, degassing equipment, coatings, thermocouple assemblies, backup insulation, sprue return filters, riser inserts and more.

- Improved metal quality

- Reduced scrap

- Increased process efficiency