Stalk and Riser Tubes

Overview

Within the low-pressure casting furnace, air pressure is applied to the top surface of the metal, forcing the higher quality subsurface metal up the stalk or riser tube into the mould cavity. By using the low-pressure process and advanced cooling capabilities, it produces good mechanical properties.

Pyrotek Offerings

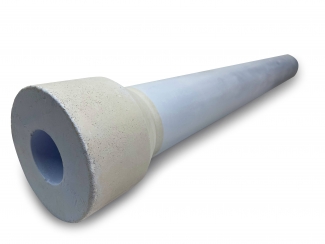

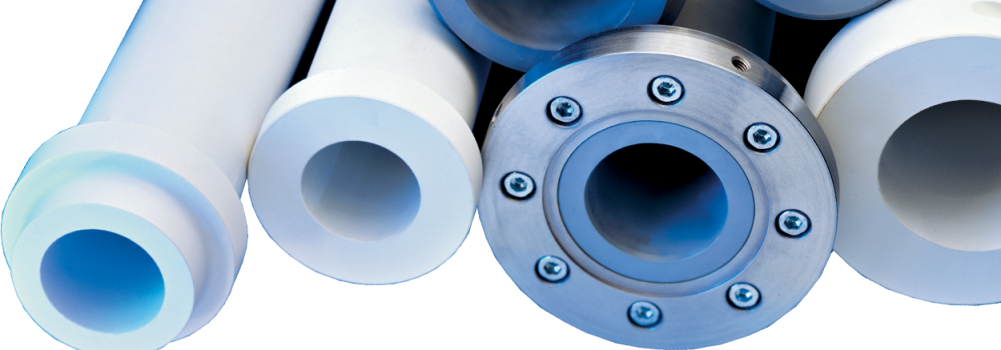

There are two general design options including T-flange and bulk flange. Stalk tubes are supplied in cast iron or industrial ceramic materials.

Cast iron stalk tubes are inexpensive, have no porosity and high mechanical strength that can be designed to customer specifications. Pyrotek also offers design and casting options to extend life and address iron pickup concerns.

Ceramic material options include Pyrocast FS80LP, dense fused silica (DFS), aluminium titanate (AlTi), silicon ntride (SiN), and silicon aluminium oxynitride (Sialon). Ceramics are chosen for their insulation values and long service life.

- Variety of stalk tube material and design options

- Local Pyrotek sales engineer support

- Local inventory options available

- Cast Iron Stalk Tubes

- Pyrocast FS80LP Castable Stalk Tubes

- Dense Fused Silica Stalk Tubes

- Aluminium Titanate Stalk Tubes

- Silicon Nitride Stalk Tubes

- Silicon Aluminium Oxynitride Stalk Tubes

| 298 Stalk Tubes EN | Datasheet | English |

| 1543 Pyrotek FS80LP Castable EN | Datasheet | English |

| 1858 LPDC SC31MX Stalk and Riser Tube EN | Datasheet | English |