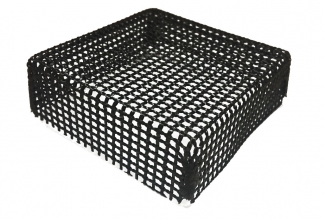

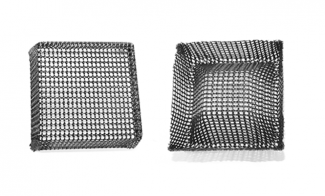

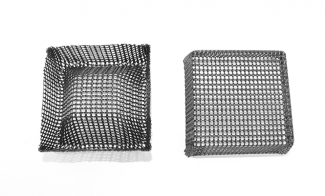

Rigid Glasweve® Filters for Sand and Permanent Mould Casting

Overview

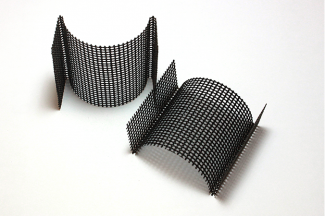

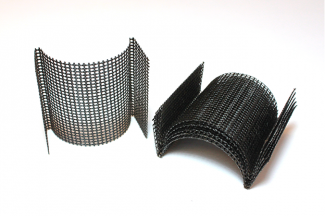

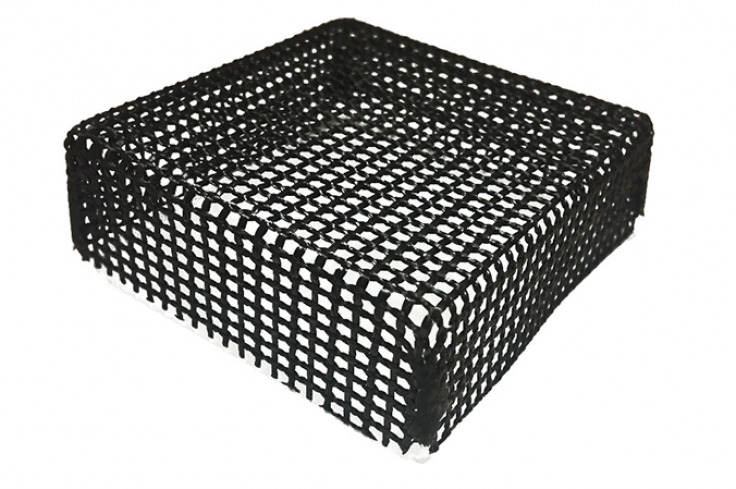

Pyrotek's Rigid Glasweve® (RGW) filter is a shaped, rigidized filter made from woven fibreglass that is used in permanent mould and sand casting applications to capture impurities in molten metal and regulate metal flow rates. RGW filters have successfully replaced traditional ceramic foam filters (CFF) with performance benefits and without process changes or modifications to existing gating.

Aluminium foundries that cast aerospace, automotive, and other commercial parts see process benefits when using RGW filters. Benefits include more consistent pouring times, easier recycling of gating, reduced abrasion on moulds and mould coatings, and improved fit with the filter pocket to prevent metal bypass. RGW filters are remelted with the gating. The filters float to the top of the melt and are removed during regular fluxing and dross removal. Compared to CFFs, Rigid Glasweve filters provide foundries with a more cost-effective solution with no distinguishable difference in casting quality.

Pyrotek Offerings

Pyrotek Rigid Glasweve® filters are manufactured with tight dimensional tolerances—within 0.5 millimetres—and are available in a variety of shapes, sizes, and materials to fit filter pocket dimensions and match flow rates of 10, 15, 20, and 30 pore-per-inch (ppi) CFF filters. Since the weave and shape of the filter affect the flow rate, Rigid Glasweve filters can be designed to replicate existing flow rate through the filter to not alter the casting process.

- Indistinguishable casting quality as CFF

- Increased savings and process efficiency by remelting gating

- More consistent pour times and improved pouring consistency (particularly beneficial for robotic pouring systems)

- Reduced wear on mould and mould coatings

- Tight dimensional control in manufacturing Rigid Glasweve filters result in reduced or completely eliminated metal bypass

| 1706 Rigid Glasweve Filters for Sand and Permanent Mould Casting EN | Datasheet | English |