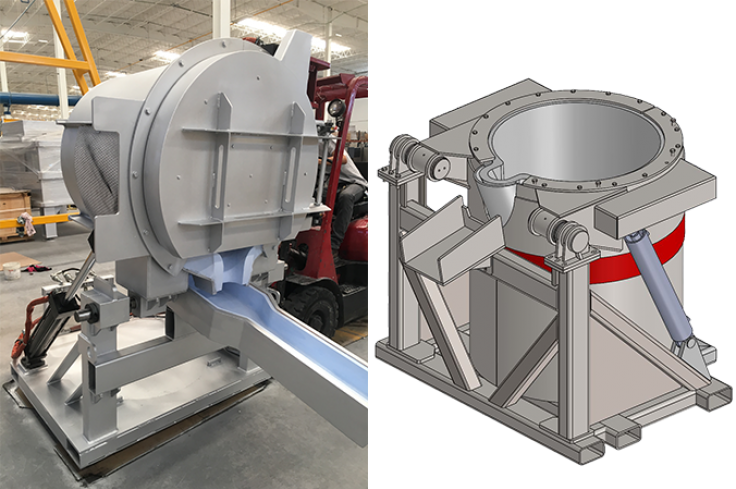

Hydraulic-Tilting Transfer Ladle

Overview

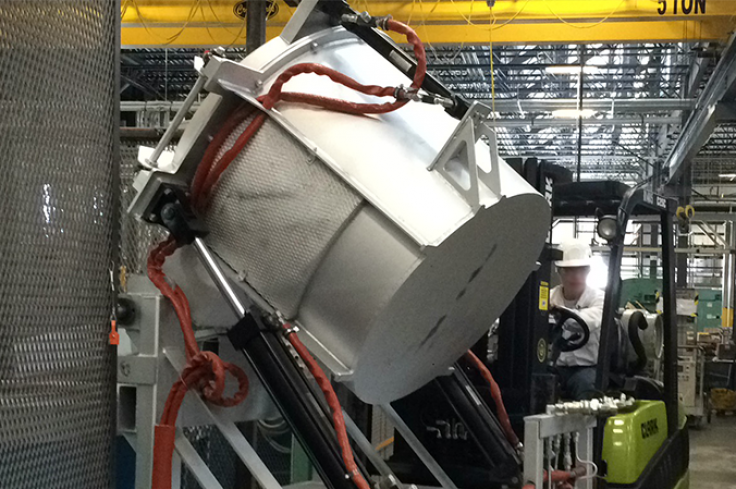

Pyrotek’s hydraulic-tilting transfer ladle system delivers enhanced safety, advanced control, and improved metal quality. The hydraulic design provides a smooth and predictable level of control to the tilting motion, so an operator can minimize turbulence when pouring. Some designs eliminate the need for the ladle to be repositioned during a pour. Since Pyrotek located the axis of the tilt rotation near the spout, the location of the pouring stream of metal is constant. This results in a more accurate delivery and less spilled metal.

Additionally, many of these designs include a hydraulically actuated cover system. When the cover can be opened and closed, without requiring the operator to exit the truck, it can be consistently used to reduce heat loss and the risk of splashed metal.

Where possible, the transfer ladle incorporates a precast and fired refractory liner, which is cast and fired in controlled conditions for optimal performance. Pyrotek has many different refractories and works with each operation to determine which materials suit a specific application. The precast liner also offers the benefit of quick and easy replacement. A new liner and engineered insulation kit can be shipped to the customer, and, in most cases, can be replaced and returned to service in a day.