Granulated Fluxes

Overview

Granulated fluxes are designed to improve melt quality and cleanliness, decrease metal loss from dross formation, and enhance overall cast quality for all casthouse and foundry operations. They are made with the same starting materials as powder fluxes, but their enhanced efficiency allows for an up to 50 percent reduction in the application rate when compared with powders. These fluxes are designed mostly for cleaning and drossing by injection, with variations in recipes to accommodate for melt temperature, exothermicity, or specific chemistry requirements of the various customer processes.

Pyrotek Offerings

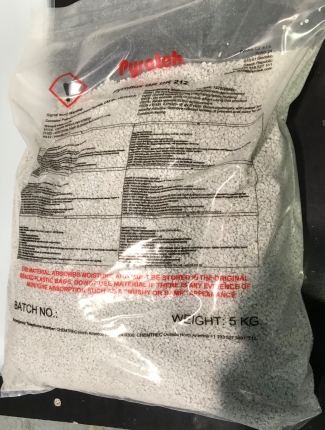

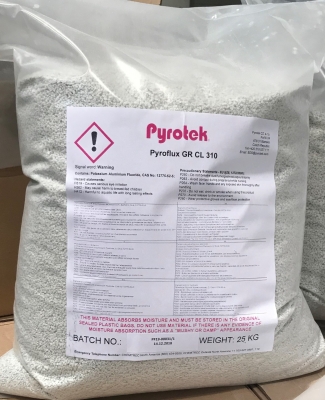

Pyroflux GR, Pyrotek’s granulated flux product line, features a large range of recipes and products. Whether for the casthouse or foundry, Pyroflux GR can be utilized to improve overall processes and end-product quality. Pyroflux GR will reduce dust and furnace filter clogging due to the larger granule size. These fluxes are offered in a nominal grain size of 1–3 millimetres (0.04–0.12 inches) specifically designed for injection, delivering improved efficiency compared to powder fluxes. For more information about the specific recipes offered, see the resources below.

Applications

- Inclusion cleaning

- Dross drying

- Grain refining

Considerations when choosing a recipe

- Metal/furnace operation temperature

- Alloy chemistry or type of metal used

- Flux addition technique

| 1384 Pyroflux Granulated (GR) Foundry EN | Link | |

| 1352 Pyroflux Granulated (GR) Casthouse EN | Link | |

| 1637 Granulated Foundry Flux Flyer EN | Link | |

| 1286 Flux Definitions and Use Guidelines EN | Link | |

| 1389 Granuflux Casthouse EN | Datasheet | English |

| 1390 Granuflux Foundry EN | Datasheet | English |

| 1883 Pyrotek Granulated Grain Refiners (Pyroflux GR GR) EN | Datasheet | English |