Degassing Systems

Overview

The aluminium industry today requires strict metal quality standards to prevent part failures in critical components of automobiles, airplanes and machinery. Degassing systems use an inert gas to remove hydrogen from molten aluminium to improve metal quality. Inclusions can lead to reduced fluidity, increased porosity, loss of mechanical properties, poor surface finish, broken tools, lack of pressure tightness and reduced corrosion resistance.

Pyrotek Offerings

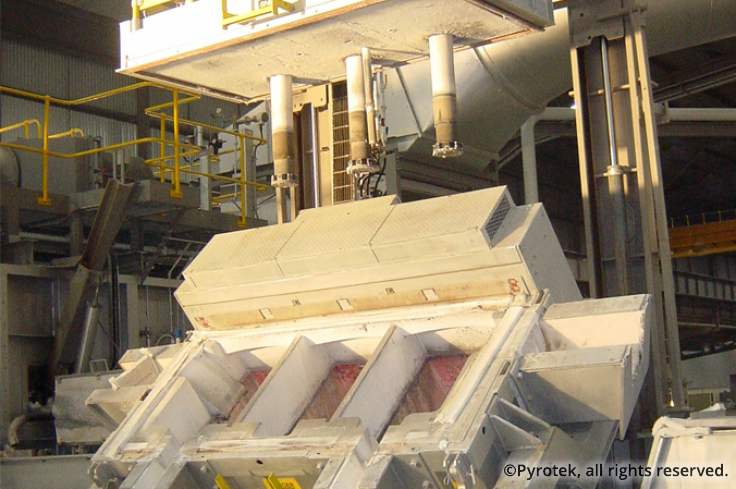

Most well-known to the aluminium industry are Pyrotek spinning nozzle inert flotation (SNIF) degassing systems. They are available as in-line or in-furnace degassing units that employ one to four nozzles depending on application and hydrogen reduction requirements. The system's spinning nozzle design disperses process gas evenly around the nozzle, stabilizes flow from the nozzle in an outward direction and protects it from inadvertent strikes by “rocks” in the chamber. In-furnace SNIF systems can be stationary or portable.

Pyrotek also manufactures STAR rotary degassing systems, used with melting and holding furnaces and transfer crucibles or ladles. Models are available in a variety of configurations including fixed, mobile, or hoist mounted and optionally available with flux injection modules. Most rotary degassing systems available incorporate specially designed shafts, rotors, baffles, tooling and control systems to ensure consistent and efficient degassing operations. They are specifically designed for long-lasting, reliable operation in harsh molten aluminium environments.

Pyrotek also provides stationary degassing tubes which inject inert gases through specially designed ceramic or graphite shapes.

For these and other degassing systems, from a variety of manufacturers in the aluminium industry, Pyrotek serves as a supplier of consumables.

- Optimal process gas bubble dispersion throughout the melt

- Reduced dross formation

- Increased metal quality

- Expert engineering design

- Expertly designed

| Degassing Diffusers | Link | |

| Metal Degassing | Link | |

| 1501 STAR 3000 EN | Datasheet | English |

| 1520 STAR 3500 EN | Datasheet | English |

| 1328 SNIF SHEER P-240Ui In-Line or U-Flow E4 | Datasheet | English |

| 1367 SNIF SHEER NEO Nozzle E4 | Datasheet | English |

| 1558 Pyrotek SNIF Sheer NEO Nozzle Assembly EN | Datasheet | English |

| 164 SNIF Stator Shaft and Rotor Assemblies E4 | Datasheet | English |

| 414 SNIF HD-2000 EN | Datasheet | English |

| 558 SNIF SHEER NEO P-30HB P-30i E4 | Datasheet | English |

| 561 SNIF SHEER R-140HB P-140HB P-140i E4 | Datasheet | English |

| 562 SNIF SHEER R-140UHB P-140UHB P-140Ui E4 | Datasheet | English |

| 600 SNIF TD-1500 E4 | Datasheet | English |

| 613 SNIF Trough Airlock E4 | Datasheet | English |

| 435 SNIF PHD-50 E4 | Datasheet | English |