Metal Level Control Systems and Components

Overview

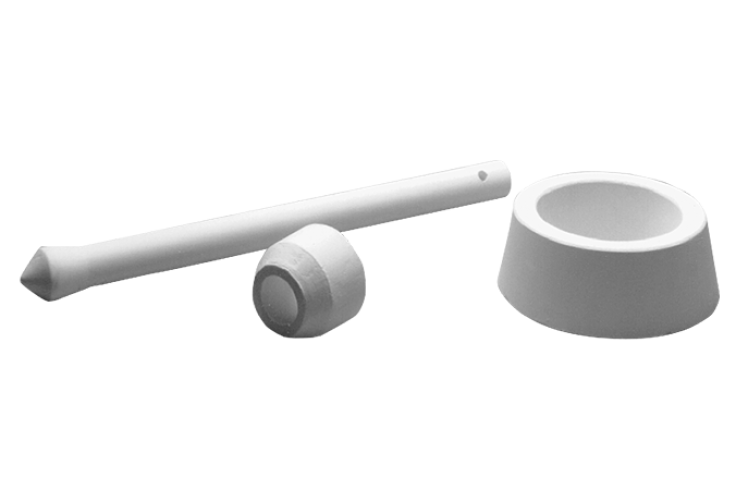

The metal level control system, called a steady eddy, is used in the headbox for continuous sheet casting. This unit maintains the flow of metal into the headbox holding the molten bath at a constant level. The control components consist of a ceramic float, graphite plug or the complete steady eddy stem with plug.

Pyrotek Offerings

Pyrotek offers complete steady eddy assemblies that will last several years with proper treatment. The floats and graphite plugs with stems need to be replaced periodically. The float (sometimes called a “pancake”) is a round rigidized ceramic material with nuts attached to the steel frame. The metering system has a graphite plug with a steel rod, protected by a ceramic coating. The plugs can be machined to conform to the drilled hole in the headbox. The typical plug is 3.962 cm x 3.658 cm (1.560 in x 1.44 in OD). A set screw holds the stem in the graphite plug.

- Automatically control metal level

- Increase safety over manual control

- Steady Eddys

- Floats

- Stems