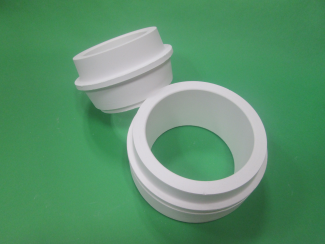

VDC Thimbles

Overview

Pyrotek VDC Thimbles are a replaceable ceramic component installed between the tabletop refractory and the transition plate of some VDC billet casting machines. They are cylindrical nozzles that utilize the head pressure of the metal in the delivery system above to increase velocity into the mould and the sump of the casting.

Pyrotek offers thimbles in a variety of geometries to accommodate all equipment designs made from two main materials. All solutions satisfy original equipment dimensional tolerances with precision casting capabilities. Both materials also deliver high strength to endure thermal stresses and minor impact loads during cleaning operations and are compatible with all refractory performance coatings.

Pyrocast NZ is the premium material with the highest thermal shock resistance and superior working surface that is smooth to assist when deskulling and hard to prevent erosive wear. Pyrocast XL offers higher strength and lower thermal expansion for high thermal stress applications.

Other applicable ceramics are available upon request. Contact a Pyrotek sales engineer for product information to meet specific project requirements.

When Pyrotek VDC Thimbles are combined with ZYP Boron Nitride Lubricoat® coatings, the Pyrotek Thimble service life can be extended.