HDC Thimbles

Overview

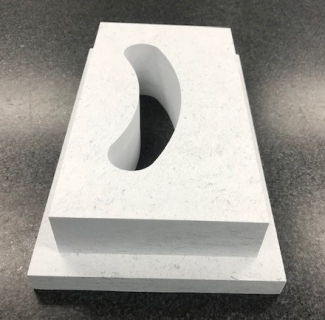

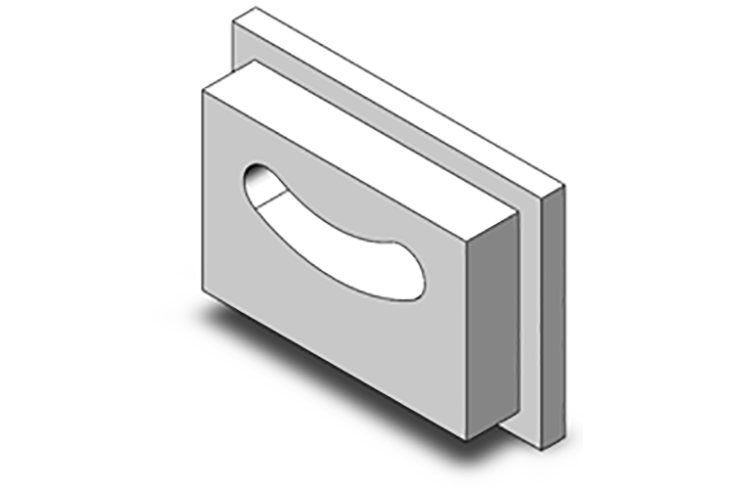

Pyrotek HDC Thimbles are replaceable ceramic components installed between the tundish and header plates of some HDC casting machines. They are rectangular plates with curved slotted apertures that provide a conduit that utilizes the head pressure of the metal in the tundish to increase metal velocity into the mould and the sump of the casting.

Pyrotek offers thimbles in a variety of geometries to accommodate all equipment designs made from a family of materials. All solutions satisfy original equipment dimensional tolerances with precision machining capabilities. All the carbon fiber reinforced calcium silicate options are non-wetting to maintain metal flow, provide toughness and strength to endure thermal stresses and minor impact loads during cleaning operations, and are compatible with all refractory performance coatings.

N-17 is the most common choice for this application with proven quality and performance. CS-1 is a preferred option for larger size thimbles due to its reduced permanent shrinkage and lower thermal expansion. N-19 is the densest material in the family of options and has shown improved performance during extended casting campaigns with minimal consequence from higher thermal conductivity.

Other applicable ceramics are available upon request. Contact a Pyrotek sales engineer for product information to meet specific project requirements.

When Pyrotek VDC Thimbles are combined with ZYP Boron Nitride Lubricoat® coatings, the Pyrotek Thimble service life can be extended.

| 1127 Refractory Board Products EN | Datasheet | English |