Potroom Clads

Overview

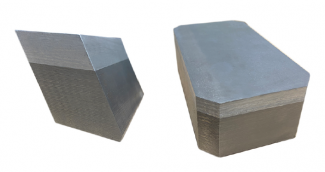

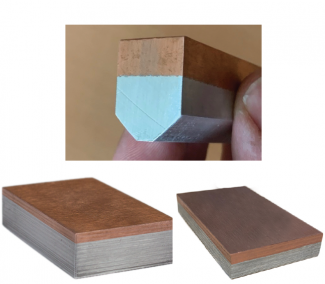

Clads are a low-resistance, high-strength joint that allows the welding of two dissimilar metals. They are for use in high-current, high-temperature, and mechanical stress environments.

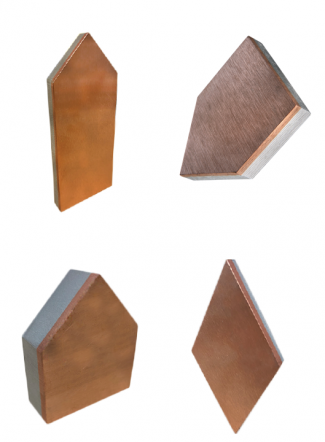

In the potroom, steel anode yokes are pre-welded to the aluminium anode rods using a trimetallic clad. This anode clad is a preformed aluminium/steel joint allowing the welding of the aluminium rod to the steel yoke, and forms a low-resistance, high-strength joint to withstand the elevated temperatures, mechanical abuse, and high current density found in the process. Cathode/collector bars are connected to aluminum flexibles of the busbar system through welded or bolted aluminum/steel or aluminum copper cathode clads. The anode ring busbar is connected to the aluminium anode stem via aluminium/copper clads.

Pyrotek Offerings

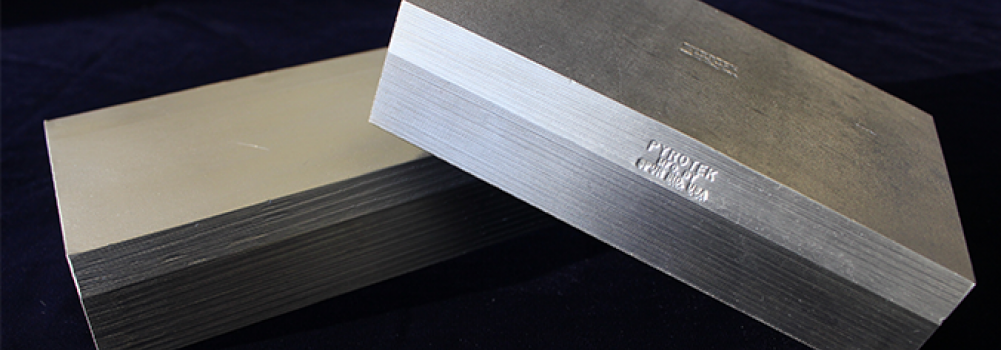

Pyrotek offers anode clads, cathode clads, anode beam clads, and zinc clads. All are available with varying levels of aluminium/steel or aluminum/copper grade options and in various sizes to meet dimensional requirements.

Pyrotek clads are formed with a high integrity metallurgical joint, which extends the service temperature and transition insert life while maintaining high electrical and thermal conductivity.

- Pyrotek clads are used on many new smelter projects and on-going maintenance spares

- Various clad designs available to suit smelter technology and preferences

- Local Pyrotek sales engineer support

- Local inventory options available

| 1838 Roll-Bonded Bus Contact Clads | Datasheet | English |

| 1839 Pyrotek Roll-Bonded Cathode Clads | Datasheet | English |

| 1843 Pyrotek Roll-Bonded Anode Clads | Datasheet | English |

| 1845 Roll-Bonded Clad Contacts - Zinc Smelting EN | Datasheet | English |