Original Equipment Replacement (OER) Transition Plates

Overview

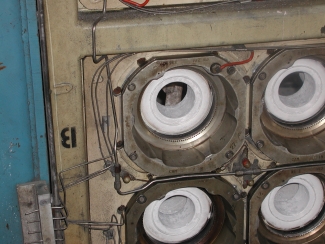

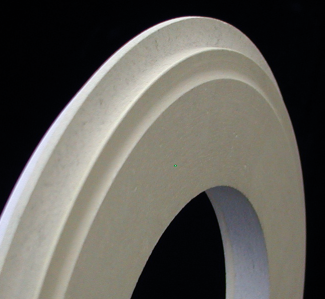

Pyrotek OER Transition Plates are replaceable ceramic components installed in both vertical direct chill (VDC) and horizontal direct chill (HDC) billet mould assemblies. They create the leading boundary of the mould before primary solidification at the casting ring. The axisymmetric transition plates for VDC applications are available in a full range of diameters and thickness. Similarly, Pyrotek’s HDC transition plates can be manufactured in almost any diameter and aperture geometry desired.

Pyrotek offers transition plates from three carbon fiber reinforced calcium silicate materials:

- The industry standard ceramic is N-17 with decades of proven performance. It delivers optimal thermal performance to prevent premature solidification, strength to overcome thermal stress under constraint in the mould, and toughness to endure thermal cycling of VDC applications.

- To extend service life of larger diameter transition plates, CS-1 is the preferred choice. This material maintains the superior thermal and mechanical properties of N-17 while providing less permanent shrinkage and lower thermal expansion to maintain mating in the assembly and reduce thermal stress of the larger diameters respectively.

- Like CS-1, N-600 is commonly used in large diameters and delivers reduced permanent shrinkage, but it has a higher thermal conductivity and thermal expansion coefficient.

No matter what material is used, all Pyrotek OER Transition Plates are precision machined to satisfy customers’ stringent dimensional tolerances, and those of original equipment manufacturers.

| 1818 Pyrotek Transition Plates VDC and HDC EN | Datasheet | English |

| 1127 Refractory Board Products EN | Datasheet | English |