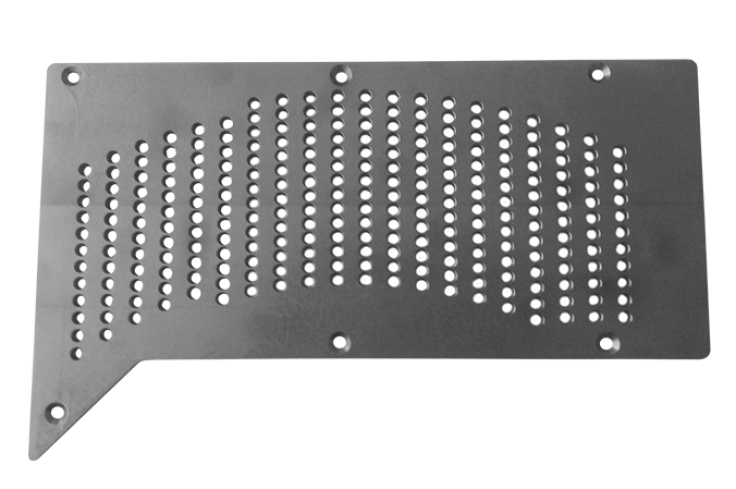

Deadplates

Overview

Deadplates protect and help cool a newly formed hot container as it moves from the IS forming machine to the conveyor. As the containers are removed from the mould by the take-out holders, they hover briefly on a cushion of air forced through holes in the deadplate, cooling and helping to form the bottle before being taken to the conveyor by the sweep-outs. As the result of brief contact, deadplate material must not thermally or physically check the hot glass. Additionally, it must withstand continual high temperatures and tough physical demands during maintenance—operators frequently stand on the deadplate during IS machine maintenance.

Pyrotek deadplates have long life, can withstand abuse from crashes and rough handling and come in various materials in assorted sizes.