SIVEX Ceramic Foam Filters

Overview

Pyrotek's SIVEX® ceramic foam filters (CFF) are used to filter and clean aluminium used for beverage can applications, aircraft alloys and other premium aluminium applications. They are a proven, cost-effective way to remove inclusions from aluminium melts.

Pyrotek Offerings

CFFs offer a practical and cost-effective alternative to existing systems used in the casthouse such as deep bed technology and furnace treatments involving porous plugs and gas fluxing. Pyrotek's high-performing SIVEX filters are available in various sizes and grades to improve melt quality and ensure that optimal filtration efficiency is achieved. Pyrotek also offers systems, such as the SIVEX filter box filtration system.

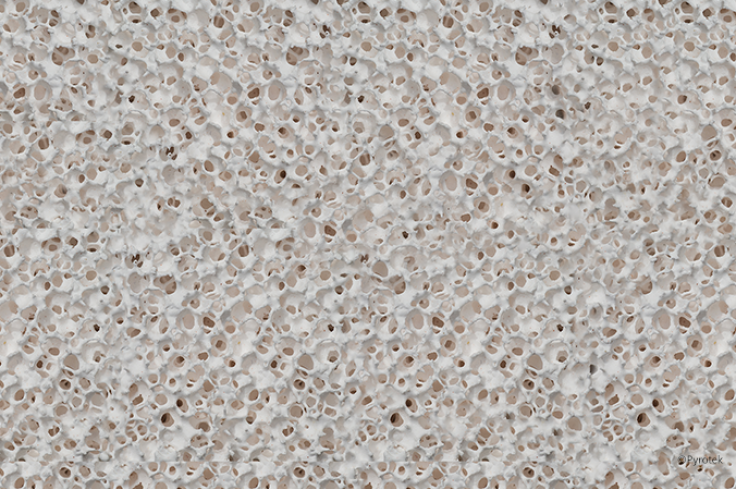

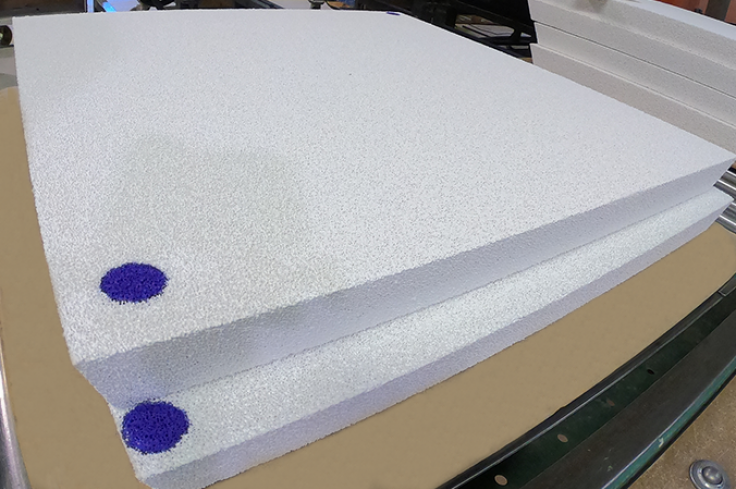

Ceramic foam filters are composed of phosphate-bonded, high-purity aluminia that gives each filter cell a high surface area. This high surface area allows the filter to attract inclusion particles much smaller than the cell itself. The reduced cell size leads to a decrease in the metal flow rate, which increases the amount of molten metal in the recommended velocity range. Cell dimensions are tightly controlled in the manufacturing process, leading to consistent filter performance. The filters are available in sizes from 17.8–66 centimetres (7–26 inches) and in filter grades of 10 to 100.

Installation and maintenance of the filters is simple and can be incorporated into any in-line process system. Alloy changes are easy to perform and there are standardized blue preheat dots on all filters.

- Consistent performance

- High-filtering efficiency

- High strength

- Excellent resistance to molten aluminium

- Can be easily incorporated into any system

| 555 SIVEX EN | Datasheet | English |

| 565 SIVEX Applications Guidelines E4 | Datasheet | English |