In-line and In-furnace Degassing Consumables

Overview

Aluminium degassing systems require durable consumables to help prevent downtime and add value to a casthouse operation's metal treatment process. Pyrotek manufactures and supplies a variety of components for in-line and in-furnace degassing systems, from shafts and rotors to troughs. Our global network of application engineers offers in-plant consultations to help determine the best consumables to meet process requirements. For information on Pyrotek consumables for Pyrotek's own SNIF degassing systems visit www.pyrotek.com/snif.

Pyrotek Offerings

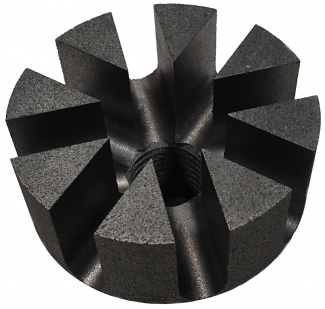

Shafts and Rotors

Pyrotek shafts and rotors for metal degassing are made from ZX-grade graphite, which has twice the oxidation resistance of standard graphite. They are durable, improve hydrogen removal, and result in minimized turbulence and oxide generation. Pyrotek degassing shafts and rotors are available in several sizes, shapes, and designs.

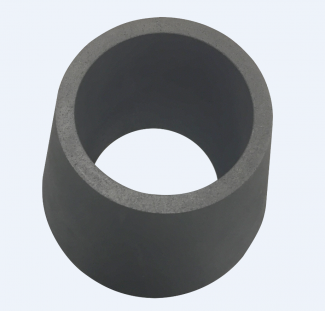

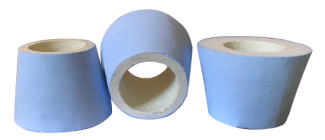

Shaft Seals

Pyrotek graphite shafts can be paired with many different rotor types and are available in multiple lengths and diameters. Pyrotek degassing shaft seals are made of a thin round ceramic fiber paper (coated with graphite) and are used as sealants between shafts and degassing units in degassing processes. These seals allow almost no creep relaxation, which greatly reduces the need for shaft tightening.

Additional Consumables

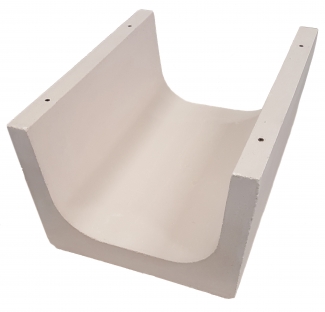

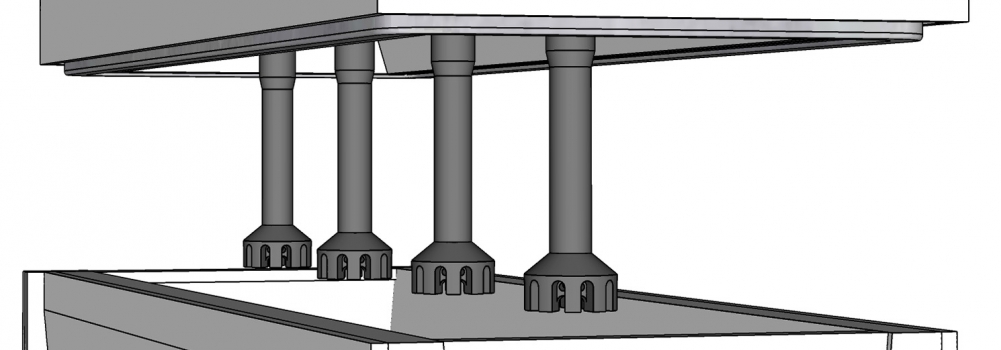

- Launders are available in several ceramic castable material options that are resistant to erosion and mechanical damage from molten aluminium. The troughs are generally wider and deeper than standard casting troughs and allow shafts and rotors to be submerged in molten aluminium. The refractory lining is lightweight and non-wetting.

- Baffles are available in several castable material options that are resistant to erosion and mechanical damage from molten aluminium. They are lightweight and non-wetting. For quicker delivery and replacement, Pyrotek offers machined baffles as an alternative.

- Pyrotek splash guards protect the shaft and degassing system from molten aluminium splash. The guards are made from ZX-grade graphite, which has high oxidation resistance. Pyrotek also offers a vacuum-formed ceramic fiber material as an alternative for graphite splash guards.

- Pyrotek's degassing gasket seals meet an aluminium operation's required temperature resistance, size, density, and durability. They typically are ceramic ropes in a single or double braid, embedded into high-temperature fibreglass fabric. The gaskets are available in many densities, thicknesses, and heat tolerances.

- Pyrotek offers a full line of coatings. Refractory protective coatings improve performance and extend service life, while safety coatings help prevent explosions.

- Consult with a sales engineer about other possible consumables and materials, as some are not described on this page. They also will help identify the most appropriate product and material combinations for each application.