Headboxes and Tundishes

Overview

Headboxes and tundishes are reservoirs where molten metal is held in a steady state as it enters from a launder and exits to a continuous sheet casting tip. They are used for vertical and tilt casters while most horizontal casters use a tundish or casting tub.

Pyrotek Offerings

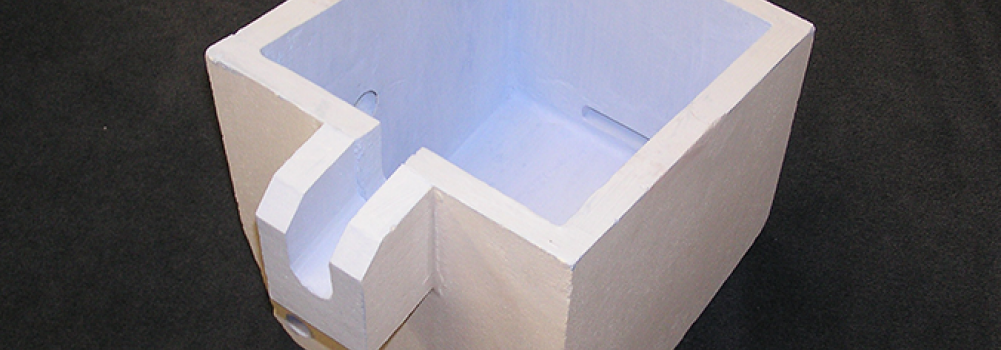

Vacuum-formed headboxes are one-piece high-purity alumina silica fibre forms that eliminate metal leakage. The alumina silica fibres are bonded to create a smooth, homogeneous, finished surface that is thermal shock resistant and has low thermal conductivity. With proper treatment, they are reusable for multiple casting campaigns. These insulating, lightweight shapes are custom formed for ease of installation and maximum performance at the lowest total cost. Headboxes are available in variable heights and wall thickness for standard design vertical casters or tilt casters. Head level control notches, feedholes and surface coating can be added at the factory to prolong product life. Headboxes are also available in higher density options for added durability.

Pyrotek’s new high-density, vacuum formed headbox (HD47 VF), designed for vertical and/or tilt casters, is formulated with a higher density than the previous vacuum formed headbox, making them more robust and durable than others on the market, while remaining lightweight and cost-effective. The enhanced design helps to better secure the headbox into place to avoid shifting and safety concerns. A premium option features a fibreglass outer covering for additional strength and longevity.

- One-piece design eliminates leaks

- Insulated to maintain metal temperature

- Thermal shock resistant

- No preheating required, but recommended

- Lightweight

- Headboxes

- Tundishes

| 1641 HD47 VF Headbox Flyer EN | Flyer | English |

| 632 Vacuum Formed Shapes for Continuous Sheet Casting EN | Datasheet | English |

| 1276 Pyrocast 82 EN | Datasheet | English |

| 1127 Refractory Board Products EN | Datasheet | English |