Transfer Ladle Preheating Systems

Overview

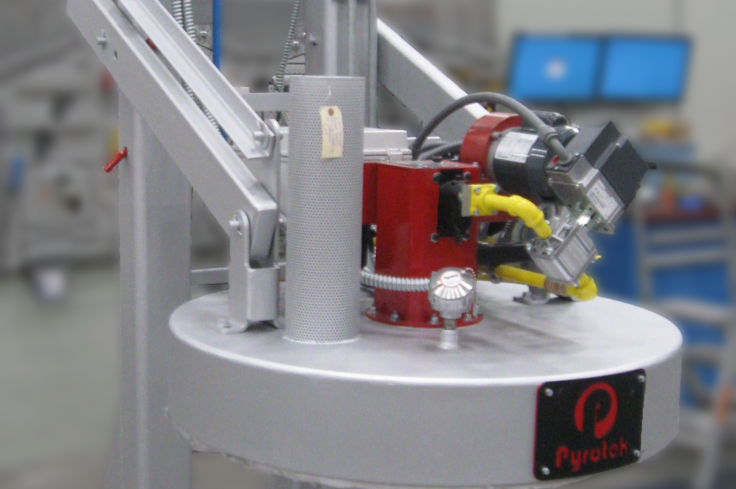

A ladle preheat system is a stand-alone station with a burner, system control center, and movable heater assembly inside of an insulated cover. The heater and cover assembly is raised and lowered above open ladles. These systems are typically designed for ladle capacities of one-half to two tonnes (1,000 to 4,000 pounds). Gas and electric power options are available, and equipment controls can be customized to customer needs, ranging from advanced temperature control options to manual controls.

For aluminium foundries globally, Pyrotek’s ladle preheater systems provide safe and easy operation, take up little space, and offer flexibility and customization in design.

Foundries already using the technology have discovered the energy savings and process efficiency created, a reduction in maintenance downtime, and seen the service life of their refractory-lined transfer ladles maximized.

“It’s crucial that our customers get the highest performance from their transfer ladles and have the safest, most efficient process of preheating them,” says Mike Tomassi, Chief Engineer at Pyrotek’s Cortland, New York, USA, facility. “Our transfer ladle preheat systems help operators properly heat their vessels so they can spend more time operating and less time in maintenance.”

Benefits

- Helps ensure full service life of refractory lined vessels

- Uniform heating of inner surface

- Low energy consumption

- Safe and easy operation