Thimbles

Overview

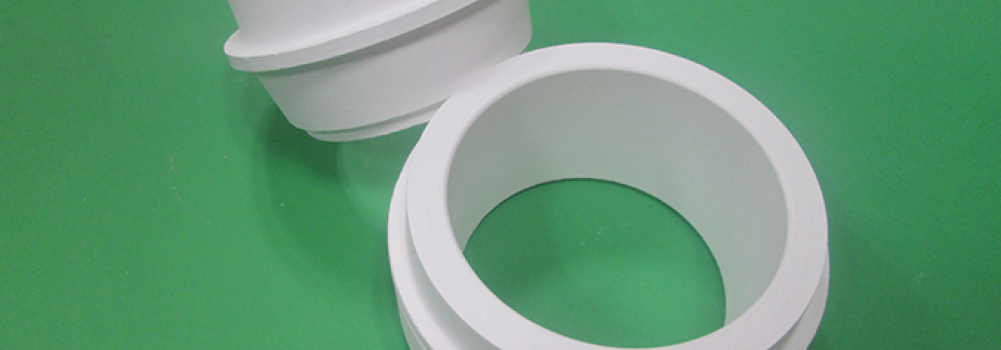

Pyrotek thimbles are a replaceable ceramic component installed between the tabletop refractory and the transition plate of some VDC billet casting machines. They are cylindrical nozzles that utilize head pressure of the metal in the delivery system above to increase velocity into the mould and the sump of the casting. For vertical direct chill casting (VDC), these components are positioned in the metal delivery system between the tabletop refractory on the top of the billet casting table and the transition plate (a.k.a. thot top ring) in the top of the mould. For horizontal direct chill casting (HDC), they are fitted between the tundish and the header plates fitted in the moulds. Thimbles are subject to high metal velocities and cleaning between every cast, so they must resist erosion and wear. Geometric stability at temperature is also important for thimbles because they are installed between two other components. Therefore, a low thermal expansion coefficient is important to minimize joint maintenance and reduce the risk of metal penetration in those joints.

Thimbles are typically cylindrical tubes with very smooth working surfaces to reduce friction and minimize mechanical attachment of the skull. At one end they have either a shoulder to accommodate mastic to seal the joint to the tabletop refractory or tundish, or a radial groove to facilitate a ceramic rope ring and mastic to seal the joint. In the middle of the thimble, there is often a flange to fasten the component onto the casting equipment, or a groove to accept a split flange to serve the same purpose. At the opposite end, a bevel is often designed around the circumference to create a taper joint between the transition plate using ceramic paper between the two components as a seal. In contrast, some assemblies mate to the top surface of the transition plate or header plate and are sealed mastic.

Pyrotek Offerings

Pyrotek offers thimbles in a variety of geometries to accommodate all equipment designs made from two main materials. All solutions satisfy original equipment dimensional tolerances with precision casting capabilities. Preferred materials deliver high strength to endure thermal stresses and minor impact loads during cleaning operations and are compatible with all refractory performance coatings. Pyrotek thimbles can be made to OEM specifications or with custom design modifications to serve unique customer requirements.

- Non-RCF refractory cast to OEM dimensional tolerances to ensure proper fit

- Dimensionally stable to manage joint seals during casting

- High erosion and thermal shock resistance to extend service life

- Hard working surfaces to resist abrasion during cleaning

- Non-wetting and smooth surfaces to improve deskulling and metal flow

| 620 Pyrotek Thimbles EN | Datasheet | English |