Casting Tips and Nozzles

Overview

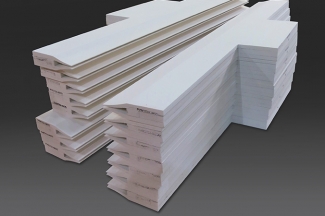

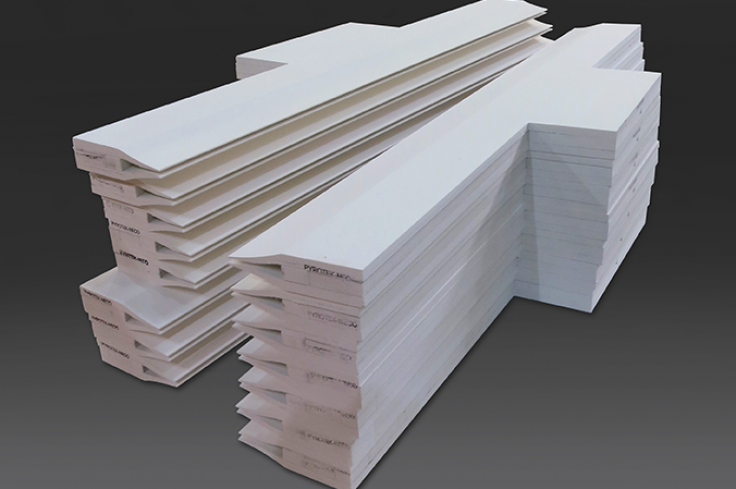

Casting tips, often referred to as casting nozzles or injectors, determine the width of the aluminium sheet during continuous casting. Casting tip sections, in conjunction with spacers, create a cavity allowing for the flow of metal through the casting tips just before solidification of the sheet.

Pyrotek Offerings

Mutiple design options are available in hard and soft tip variations. Pyrotek offers complete casting tip assemblies that are ready to insert into the casting tip base on arrival, thus eliminating any need to cut or assemble casting tips on-site.

Pyrotek's R3 hard casting tips are specifically engineered and optimized for the production of high quality, aluminium continuous sheet casting for twin-roll Casters. Pyrotek R3 material is a formulation of ceramic fibres bonded with an inorganic, silica binder. They are dimensionally stable, thermal shock resistant and do not cause outgassing. Pyrotek R3 casting tips implement the highest standards in surface finish and leading edge cosmetics to ensure a smooth and consistent cast.

Pyrotek offers all of the component pieces required for continuous casting tip assemblies such as end dams, spacer boards, internal baffles, boron nitride coatings, Fiberfrax paper and glue for tip assembly.

Pyrotek also provides other formulations of material for casting nozzles for block casters and belt casters.

Wheel and belt casters can use machined N-17 or B-3 boards.

- Engineered and optimized for aluminium sheet casting

- Excellent surface cosmetics for a smooth and consistent cast surface

- Dimensionally stable

- Thermal-shock resistant

- Does not produce outgassing

- Twin Roll Caster Tips

- Block Caster Nozzles

- Wheel and Belt Caster Nozzles

- Belt Caster Nozzles

| 1388 Pyrotek R3 Continuous Casting Tips EN | Datasheet | English |

| 1127 Refractory Board Products EN | Datasheet | English |

| 1424 Belt Caster Feed Nozzle F4 | Datasheet | français |

| 1424 Belt Caster Feed Nozzle S4 | Datasheet | español |

| 1578 Pyrotek R3 Tip Sections Unpacking Guide EN | Datasheet | English |