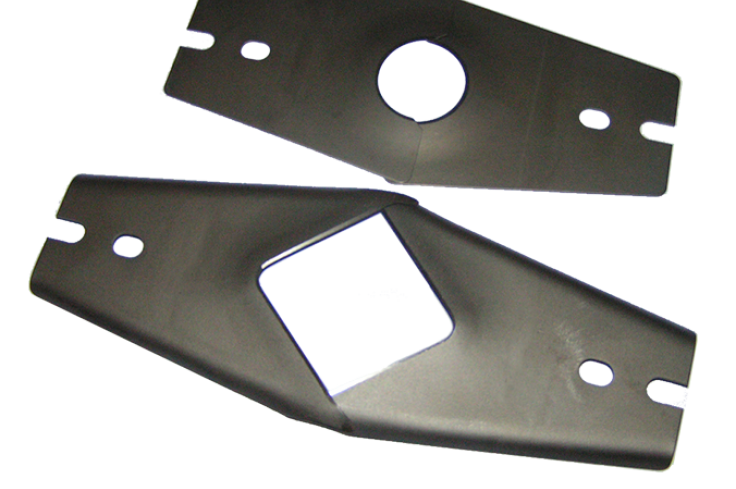

PUTSCH Shear Blades

Overview

PUTSCH shear blades are made of high-quality, heat resistant special steel. Stringent quality controls are applied to every blade produced.

- Every shear blade pair for double, triple and quadruple-gob operation has the same pressure and wear at the cutting edge.

- The shear blades are bead-blasted to increase the surface area. This causes better retention of the cooling liquid, which optimizes the cooling effect. A special hardening process ensures that a high percentage of the materials alloying components are changed into carbides.

- The carbides guarantee that the hardness of the shear blades is preserved even if the shear blades are accidentally overheated.

- The shear blades have excellent emergency running properties in overheated situations.

- Custom blades can be manufactured for specialty glass applications.

- Special grind on blades is available.

- Re-sharpening services are available to reduce overall shear blade expenditure.

PUTSCH shear blades feature:

- Optimum cutting dynamics with partial flexibility in the clamping area, combined with the tempered cutting area.

- Parallelism and planimetry of the cutting edges within tight tolerances offer even, minimal stress on the cutting edges in addition to excellent operating reliability.

- Exceptional durability with minimal wear and tear due to low cutting area pressure.

- Special relief grinding of the upper cutting edge avoids shear blade marks.

- Various cutting edge angles for special applications.

- Effective cooling agent adhesion due to the matted shear blade surface allows adjustment of the shear blade temperature for an optimum cutting result.

- High form stability of shear blades under stress due to the arrangement of side stamping developed from practical experience.

- Regrinding is possible with high-quality PUTSCH shear blades. The reground blades perform equal to new blades and thus lower the unit cost of the shear blade.