Lead Recovery Systems

Overview

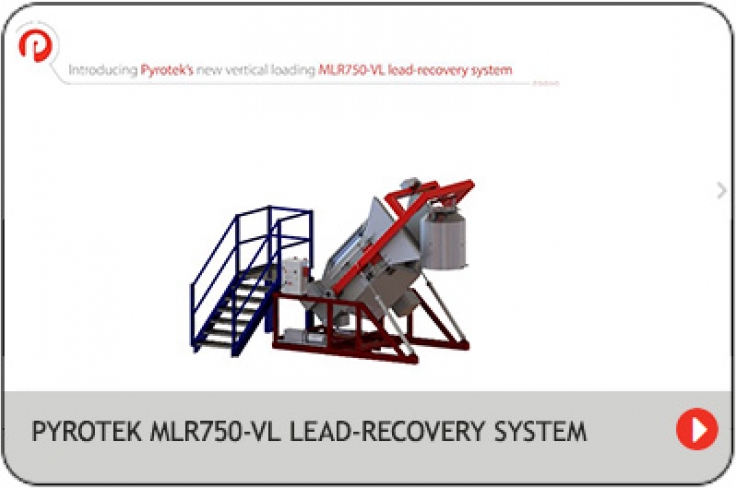

Recovering lead from dross and process waste allows producers to reclaim valuable metal in-house and reduce costs. Pyrotek's proprietary lead recovery system technology is designed and built for dross volume producers, such as lead-acid battery manufacturers, anode and strip producers and secondary metal refiners.

Pyrotek Offerings

Pyrotek's lead recovery system utilizes a thermo-mechanical device to separate free lead from material mixtures and top drosses. It is a highly efficient in-house industrial system that recovers nonferrous metal from industrial process wastes and top drosses, including “rich wet” drosses, ash, dust and high-low melting metal mixes. The recovered lead is both technically and commercially acceptable for reuse in the process, and any lead-oxide residues can be sold.

- Reduction in the volume of virgin lead bought at LME rates

- Reduced volume of residual skimmings being disposed

- Increased value of lead-oxide residual skimmings that can be sold

- Easier to use than other systems on the market, with greater ease in loading the drum

- Recognized technology by the European Commission’s Integrated Pollution Prevention and Control Directive

| 1430 Pyrotek Lead Recovery Brochure EN | Brochure | English |

| 1728 MLR750 VL Lead Recovery System Flyer EN | Flyer | English |