Vertical Direct Chill (VDC) Slab-Rolling Ingot Casting

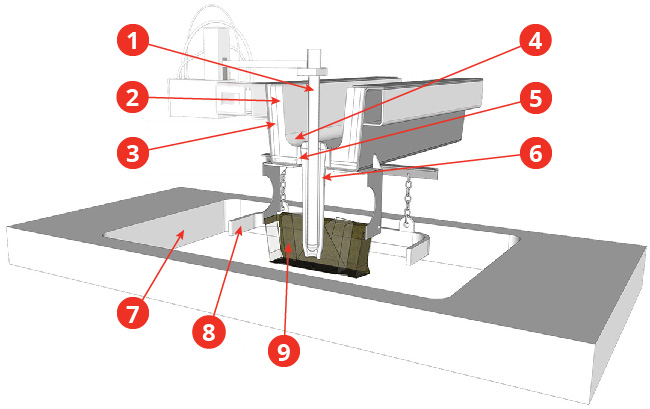

Key

- Control Pins

- Troughs and Launders

- Backup Insulation

- Pyrotek Coatings

- Spout Seals

- Spout/Transfer Tubes

- Casting Mould Lubricants

- Skim Dams

- Distribution Control Devices

The majority of the aluminium produced is first cast into ingots with large cross sections prior to further processing into sheet, plate or foil. Ingots produced from vertical direct chill (VDC) casting are typically scalped and then processed (rolled) into sheet and plate products for the packaging, building/construction, and transportation markets. T-ingots that are DC cast are sold for remelt and further processing. Metal quality and minimal downtime are key to producing high-value product and scrap reduction.

Pyrotek offers proven solutions for VDC ingot/slab casting, including distribution troughs, downspouts, coatings, mastics and mortars, channel bags, combo bags, skim dams, lubricants, gaskets and seals, thermocouples and more.

Benefits include:

- Increased metal quality

- Reduced energy costs

- Reduced downtime

- Customized solutions

Related Products

Safety Coatings

Additional Information

| 1716 Vertical Direct Chill Slab Casting Brochure EN | Brochure | English |